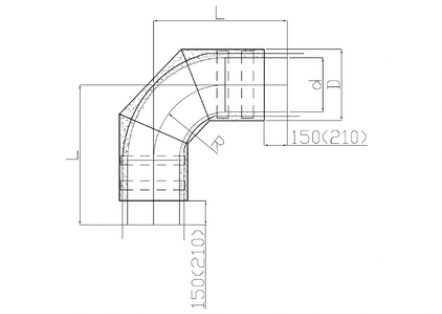

The elbow bend is used to connect the pipes in places of turns (bends). It has different lengths of arms and turn angles, which makes this element of the pipe-line multi-operated and irreplaceable. Elbow bends allow to project and build pipe-line systems with a difficult subdivided structure changing the direction of the pipe-line in a horizontal and vertical plane at any angle, and also to reduce the usage of special compensating devices (starting and bellows expansion compensators), as one or several elbow bends are places of natural self-compensation of the pipe-line.

Optionally, at the plane JSC «Isoplus Central Asia» we produce elbow bends of any angles and different factory length.

|

d, mm |

R, mm |

PE mantle |

Elbow bend angle 90° |

Elbow bend angle 60° |

Elbow bend angle 45° |

Elbow bend angle 30° |

|||||

|

Type 1 |

Type 2 |

||||||||||

|

D, mm |

D, mm |

L, mm |

m, kg |

L, mm |

m, kg |

L, mm |

m, kg |

L, mm |

m, kg |

||

|

3D (R=1,5DN) |

|||||||||||

|

32х3,0 |

38 |

125 |

- |

1000 |

10 |

1000 |

10 |

1000 |

10 |

1000 |

10 |

|

38х3,0 |

48 |

125 |

- |

1000 |

11 |

1000 |

11 |

1000 |

11 |

1000 |

11 |

|

45х3,0 |

60 |

125 |

- |

1000 |

12 |

1000 |

12 |

1000 |

12 |

1000 |

12 |

|

57х3,0 |

75 |

125 |

140 |

1000 |

13 |

1000 |

13 |

1000 |

13 |

1000 |

13 |

|

76х3,0 |

100 |

140 |

160 |

1000 |

19 |

1000 |

19 |

1000 |

19 |

1000 |

19 |

|

89х4,0 |

120 |

160 |

180 |

1000 |

24 |

1000 |

24 |

1000 |

24 |

1000 |

24 |

|

108х4,0 |

150 |

180 |

200 |

1000 |

31 |

1000 |

32 |

1000 |

32 |

1000 |

32 |

|

133х4,0 |

190 |

225 |

250 |

1000 |

41 |

1000 |

42 |

1000 |

43 |

1000 |

43 |

|

159х4,5 |

225 |

250 |

280 |

1000 |

56 |

1000 |

58 |

1000 |

59 |

1000 |

58 |

|

219х6,0 |

300 |

315 |

355 |

1000 |

97 |

1000 |

103 |

1000 |

106 |

1000 |

104 |

|

273х7,0 |

375 |

400 |

450 |

1000 |

121 |

1000 |

130 |

1000 |

136 |

1000 |

132 |

|

325х7,0 |

450 |

450 |

560 |

1050 |

164 |

860 |

150 |

786 |

140 |

720 |

134 |

|

426х7,0 |

600 |

560 |

630 |

1100 |

251 |

889 |

220 |

807 |

220 |

734 |

185 |

|

530х7,0 |

750 |

710 |

- |

1390 |

252 |

870 |

161 |

900 |

184 |

761 |

237 |

|

630х8,0 |

900 |

800 |

- |

1420 |

339 |

870 |

215 |

890 |

278 |

819 |

267 |

|

720х8,0 |

1050 |

900 |

- |

1450 |

403 |

870 |

253 |

840 |

305 |

843 |

343 |

|

820х9,0 |

1200 |

1000 |

1100 |

1700 |

522 |

950 |

347 |

780 |

348 |

820 |

510 |

|

920х10,0 |

1350 |

1100 |

1200 |

1800 |

697 |

1040 |

436 |

900 |

451 |

846 |

593 |

|

1020х11,0 |

1500 |

1200 |

- |

2000 |

881 |

1100 |

543 |

950 |

567 |

874 |

698 |

|

2D (R=DN) |

|||||||||||

| 530х7,0 | 500 | 710 | - | 1200 | 373 | 946 | 357 | 848 | 252 | 761 | 237 |

| 630 х 8,0 | 600 | 800 | - | 1200 | 387 | 945 | 430 | 848 | 282 | 761 | 248 |

| 720 х 8,0 | 700 | 900 | - | 1370 | 546 | 1066 | 564 | 948 | 391 | 843 | 343 |

| 820 х 9,0 | 800 | 1000 | 1100 | 1470 | 782 | 1073 | 656 | 990 | 656 | 820 | 510 |

| 920 х 10,0 | 900 | 1100 | 1200 | 1570 | 890 | 1132 | 780 | 1032 | 758 | 846 | 593 |

| 1020 х 11,0 | 1000 | 1200 | - | 1620 | 1015 | 1189 | 927 | 1022 | 756 | 874 | 698 |

An example of the type codes in the ordered specification:

The steel elbow bend of diameter 1020 mm, with thickness of pipe wall 11 mm, 90°, with isolation of type 1 from polyurethane foam, in polyethylene casing:

- Elbow bend St1020*11-90°-1-PUF-PEM

The steel elbow bend of diameter 1020 mm, with thickness of pipe wall 11 mm, 90°, with isolation from polyurethane foam, in galvanized casing:

- Elbow bend St1020*11-90°-PUF-GalM

Notes:

The steel part of the elbow bend can be made undivided and bent from a pipe or welded with a return or segmented bend. The thickness of the wall of the steel return or segmented bends are accepted according to the National State Standard 17375-2001, Standard 30753-2001, standard series 5.903-13 for the thickness of the main pipe. The standard sizes of produced elbow bends are shown in the table. At the request of the customer, the elbow bends can be made with different angles α. It is possible to produce elbow bends from flat steel. It is possible to produce elbow bends with increased length of arms and thickness of walls.